PD-I is a new innovation in surgical bandage manufacturing industry, which replaces conventional manual bandage rolling processes with a modern machine having a world class design to achieve international quality, high efficiency and enhanced productivity. Right from roll feeding to roll making, the entire process is automated with a unique width control assembly which eliminates human intervention in the rolling process.

PD-I comes in two models PD-IM1 and PD-IM2. PD-IM1 is completely modular in design and the machine can be dismantled and repacked. It is an export quality model designed specifically to meet the quality requirements of the international market segment. The PD-IM2 is a low cost stand alone welded structure so designed as to suit the local manufacturing environs of the Indian micro and small industries. Both the models are engineered out of steel to enhance long life of the machine, to provide hygienic conditions in manufacturing and easy maintenance. The machine measures 900mmX900mmX1500mm and weighs approximately 200 kg.

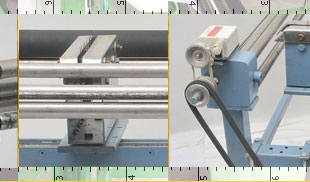

The machine comprises of a feeding sub assembly, a unique and modern width control mechanism and a rolling system. The machine is designed for both the manual as well as electric drive. There is a tachometer to measure the length of the rolled cloth. The rolling system is so designed as to take up different lengths of roll without any change of attachments.

The Automatic Bandage cloth Width Control Mechanism (ABWCM) is a unique part of the machine and manufacturing process, both of which are patented property of RA Yadav. No other machine in the world uses such a technology to provide automatic width control for bandage cloth. This width controlling process in the industry is mostly manual requiring highly skilled operators. The ABWCM is at the heart of the PD-I, eliminating manual processes, and providing quality and high value hygienic output. The ABCWM comprises of a pair of expanders which can be made to come closer to each other or move away from each other depending upon requirement of manufacturing. The width can be fixed according to the width of the bandage cloth. At present the maximum width permissible is 1120mm. Further, the distances between the expanders at entry and exit can be varied upto 100mm .

PD-I Processes and Working:

The feeding unit winds the gauze bandage cloth into a big roll called "Master Roll". The free end of the roll is fed in between the metallic and non metallic rollers and pulled further and inserted into the rolling system through the ABWCM. The rolling system assembles the driving device. The driving unit could be operated either manually or through an electric motor. On activating the driving unit, rolling starts. During rolling the longitudinal tension is provided by the feeding unit rollers and transverse tension is provided by the ABWCM. After rolling the desired length of cloth, the cloth is cut with a sharp knife, and kraft paper is rolled over it. The roll, thereafter, is disengaged from the machine, and the the split bars are pulled out from the core of the roll. The roll is cut into desired length of surgical bandages for packaging and shipment. |

|

|

|

|

|

|

| Specifications : |

|

|

|

|

|

|

|

|

| |

S.No. |

Details |

|

|

|

|

|

|

|

|

| |

1 |

Dimensions (in mm)* |

900x900x1500 |

|

|

|

|

|

|

|

|

| |

2 |

Weight (kg) |

200 |

|

|

|

|

|

|

|

|

| |

3 |

Fabrication |

Steel Construction |

|

|

|

|

|

|

|

|

| |

4 |

Winding Speed |

Variable |

|

|

|

|

|

|

|

|

| |

5 |

Input Cloth Material |

Woven fabric, blended cotton, viscose, silk |

|

|

|

|

|

|

|

|

| |

6 |

Width of cloth (minimum) |

150 mm |

|

|

|

|

|

|

|

|

| |

7 |

Width of cloth (maximum) |

1120 mm |

|

|

|

|

|

|

|

|

| |

8 |

Length measuring device |

Tachometer, mechatronic sensor |

|

|

|

|

|

|

|

|

| |

9 |

Electrical Drive specification |

Variable frequency drive; Motor: 1 HP single phase |

|

|

|

|

|

|

|

|

| |

10 |

Rolling RPM |

Variable |

|

|

|

|

|

|

|

|

| |

11 |

Work force |

1+1 |

|

|

|

|

|

|

|

|

| |

12 |

Productivity |

800 rolls per shift |

|

|

|

|

|

|

|

|

| |

13 |

Hygiene |

Can be easily decontaminated, cleansed, disinfected |

|

|

|

|

|

|

|

|

| |

14 |

Mobility |

Mobile with provision of grouting |

|

|

|

|

|

|

|

|

| |

15 |

Ergonomics |

Drudgery free operation |

|

|

|

|

|

|

|

|

| |

16 |

Alternate usages |

Embroidery, medicated bandages, printing on cloth |

|

|

|

|

| * Machine can be customized to other specifications of dimension on order. |

|

| |

|

| BIODATA OF INVENTOR: |

|

R.A. Yadav, a graduate in science & technology, has multi dimensional experience of 35 years in the field of ideation, research, design, development, invention, innovation, investigation, ToT documentation, manufacturing, quality assurance, management, coordination of S&T plans and programmes. He retired as a senior scientist from the Government of India. He is a member, guide and referee to the Institution of Engineers, India. He has to his credit publication of a number of research papers, reports and books.

He received several public awards and Certificates of Excellence by IIFS, New Delhi, Design Award from the Govt. of India, and Bharat Jyoti Award from an international organization.

He is associated with many NGOs and local bodies for bringing S&T interventions in rural technology for empowering rural India.

|

|

|